Waste Plastic Pallet Molding Machine

Advantages:

- Abundant Raw Materials – Uses widely available recycled plastic, reducing material costs and promoting sustainability.

- Simple Machine Operation – Designed for easy use with minimal technical expertise required.

- Low Investment Cost – Affordable initial investment compared to traditional pallet manufacturing methods.

- High Production Efficiency – Ensures a fast production cycle, increasing output and profitability.

- Low Maintenance Cost – Durable components and efficient design minimize maintenance expenses.

- Competitive Market Advantage – Produces cost-effective and high-quality pallets with strong market demand.

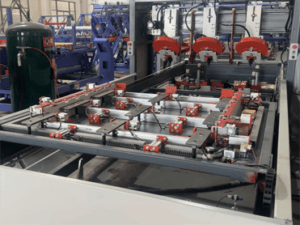

Introduction of plastic pallet molding machine

Discover our advanced plastic recycling machines for manufacturing pallets from waste plastic. Efficient, eco-friendly, and cost-effective, our solutions help turn recycled plastic into durable pallets.

Why is it a best-selling plastic pallet molding machine?

Wide Range of Raw Materials – Uses various waste plastics, including discarded plastic bottles, barrels, municipal plastic waste, paper mill waste, household plastic waste, and industrial scraps. These raw materials are easy to obtain, ensuring a stable supply. (PP,PE,HDPE)

Simple Operation & Configuration—The collected plastic waste does not need to be cleaned or pelletized. After crushing, the raw material can be used directly, reducing processing steps and operational complexity.

Cost-Effective Production – Since the raw material cost is low, the final plastic pallets are competitively priced, making them more attractive in the market.

Energy & Cost Savings – Eliminates the need for washing and pelletizing, significantly reducing electricity consumption, labor costs, and overall production expenses.

Eco-Friendly Solution – Helps reduce plastic waste and pollution by transforming discarded plastic into valuable products, contributing to environmental protection and sustainability.

Raw Materials For Pallet Production Line

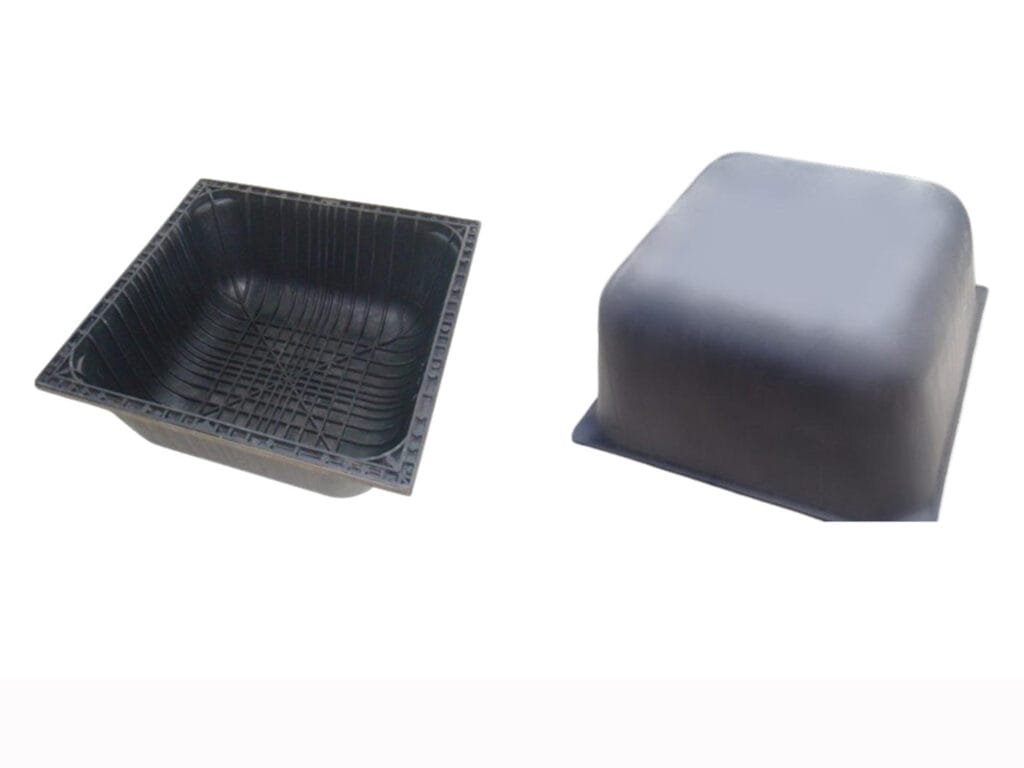

Products that can be made with Plastic Molding Machine

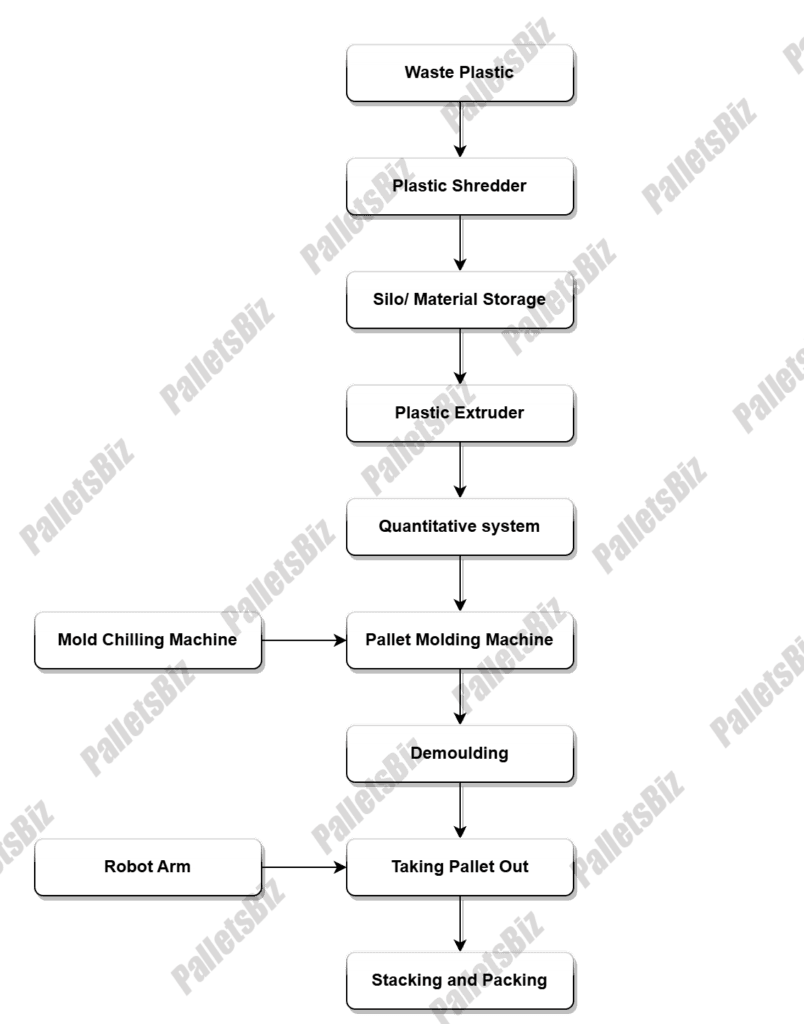

The Plastic Pallet Molding Production Line Flowing Diagram

Plastic Recycling Process

- Collection: Used plastic products, such as bottles or industrial scraps, are collected from recycling bins or waste streams. Companies like Scrap Management (as seen on their site) specialize in sourcing plastic bottles in bales for recycling.

- Sorting: The collected plastic is sorted to remove contaminants like labels, caps, or non- plastics, ensuring a pure feedstock.

- Shredding: The sorted plastic is fed into shredders, breaking it down into small flakes or granules for easier processing.

- Washing: The flakes are thoroughly cleaned to remove dirt, residues, or adhesives, producing high-quality recycled material.

- Melting: The clean plastic flakes are melted into a molten state, preparing them for molding.

- Compression Molding: The molten plastic is placed into a mold within a compression molding machine. The machine applies heat and pressure, shaping the material into a solid pallet. This method ensures uniform density and strength.

- Cooling and Finishing: The molded pallet is cooled, removed from the machine, and trimmed or finished as needed for immediate use.