Wooden Pallet Nailing Machine

Applicable pallet style: Block Type Pallet, Stringer Type Pallet

Pallet Size: 800x800mm to 1300x1300mm

Nailing Speed: 1 pcs pallet per minute

Our company manufactures high-efficiency, automated wooden pallet nailing machines. Designed for American and European pallets, our CNC models are cost-effective, stable, and PLC-controlled for precision. With pallet turnover and palletizing features, they ensure seamless, high-speed production.

Advantages of The Pallet Nailing Machine:

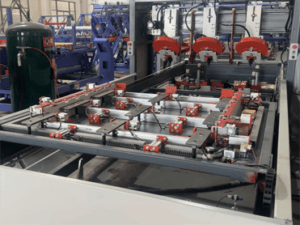

High Efficiency & Stable Operation – Equipped with a professional controller and customized software, ensuring safe, stable, and efficient production.

Precision & Consistency – Utilizes a servo motor and precision servo reducer for high mechanical accuracy, guaranteeing consistent pallet dimensions.

Versatile & Customizable – Capable of processing both American and European standard pallets, with options for customized non-standard pallets.

Easy Operation & High Speed – Simple one-person operation with manual feeding, automatic nailing, and palletizing. Touchscreen control, automated nailing at 4 nails per second, and a feeding speed of 400 pallets per 8 hours—three times faster than manual work.

Pallet Nailing Machine Models

Pallet Nailing Machine For Euro Block Pallet

Pallet Nailing Machine For Stringer Pallet

Pallet Nailing Machine For Solar Panel

Pallet Nailing Machine Horizontal Type

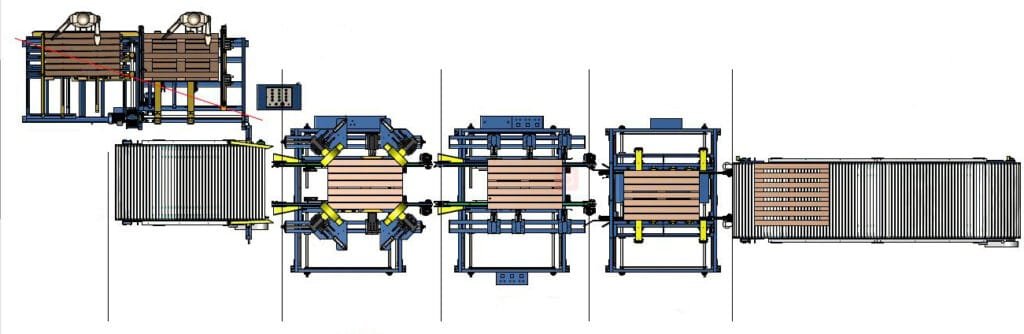

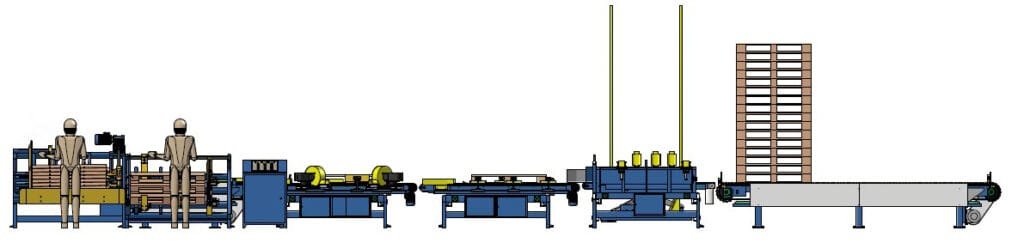

Euro Pallet Production Flow Diagram

The pallet nailing machine is designed for efficient and automated pallet manufacturing. The entire process consists of four main stages:

Nailing – Workers place wooden boards and blocks onto the machine, which then automatically nails them together to form the pallet structure.

Corner Cutting – Once the pallet enters the working area, the corner cutting machine is automatically activated, creating four chamfered edges for improved handling.

Branding – The branding machine is triggered automatically, stamping the necessary markings onto the wooden blocks of the pallet.

Stacking – The finished pallets are neatly stacked for easy packaging and transportation.

This Euro pallet production line is simple to operate and can be managed by a single worker. Depending on the pallet design, most pallets can be completed within one minute, significantly reducing labor intensity and enhancing the production efficiency of traditional Euro pallets.