Pallet Block Machine

Introduction:

The wood chips pallet block machine is a specialized piece of equipment that compresses wood chips or sawdust into sturdy, uniform blocks for use in pallet construction. It offers an efficient, eco-friendly solution by recycling wood waste into durable, high-quality pallet components.

Euro Pallet Blocks and Special Size:

145x100mm, 95x95mm, 160x95mm,145x145mm,78x78mm…

Output Capacity:

From 1 m³/day to 7 m³/day according to block sizes

Pallet Block Machine Modles

Single Head Pallet Block Machine

Double Heads Pallet Block Machine

Triple Heads Pallet Block Machine

Pallet block machine parameters

| Model | WM-D2 | WM-D4 | WM-D6 |

|---|---|---|---|

| Power | 18 kW | 23.5kw | 28.5 kW |

| Density | 500-600 kg/m3 | 500-600 kg/m3 | 500-600 kg/m3 |

| Size | 75*75-145*145mm | 75*75-145*145mm | 75*75-100*100mm |

| Capacity | 1.4-5.4 m3/24h | 2.9-10.8 m3/24h | 4.3-7.7 m3/24h |

| Weight | 900 kg | 1500 kg | 2000 kg |

| Dimension | 5000*500*1300mm | 5000*700*1300mm | 5000*900*1300mm |

| pressure | 3-5 Mpa | 3-5 Mpa | 3-5 Mpa |

| Voltage | Customization | Customization | Customization |

Pallet Block Photos

The wooden blocks produced by this equipment have a smooth surface, a moderate density, and possess high nail-holding power and waterproof performance. The density of the wooden blocks can be adjusted according to the customers’ needs and production situations, and the operation is simple.

Block Sizes & Data

Length x Width in mm

Hight in mm

Length x Width in mm

Hight in mm

Length x Width in mm

Hight in mm

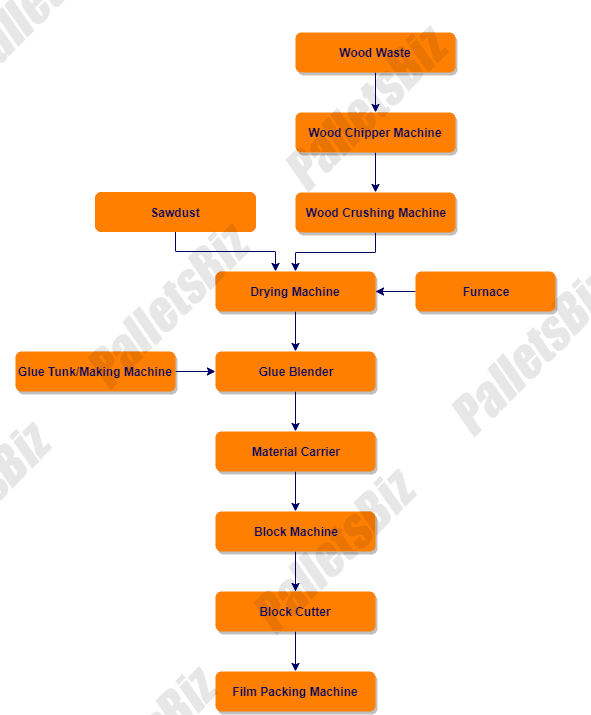

Euro Pallet Block Production Line Process Flow Chart

The production process of the pallet block production line

1. Raw Material Collection

Raw materials such as waste wood, sawdust, and wood chips are collected from sawmills and furniture factories. Contaminants like nails and plastics are removed for quality control.

2. Crushing & Grinding

Wood materials are processed through a wood crusher and hammer mill to achieve uniform particle size, essential for durable presswood pallet blocks.

3. Drying

The wood sawdust is dried to 8-12% moisture content using rotary or belt dryers, ensuring optimal bonding and preventing warping.

4. Adhesive Mixing

Dried wood particles are mixed with UF, and MUF, enhancing strength and durability. Additives may be included for waterproof properties. UF /MUF glue ratio 13-15%.

5. Compression Molding

The mixture is molded in a hydraulic press at 150-200°C under high pressure, forming compressed pallet blocks with high strength.

6. Cooling & Cutting

After cooling, blocks are cut into standard sizes like 90×90 mm, 100×100 mm, or 145×145 mm as per customer requirements.

7. Quality Inspection

Each batch undergoes moisture, density, and strength testing. Non-compliant blocks are rejected or reprocessed.

8. Packaging & Storage

Finished blocks are bundled, wrapped in plastic film, and stored in dry, ventilated areas to maintain quality.

9. Delivery & Application

These eco-friendly pallet blocks are used in molded pallet production, providing a strong, uniform, and pest-resistant alternative to solid wood blocks.