Small and medium-sized factories must consider production needs, budget, equipment performance, and ease of operation when selecting a European pallet nailing machine.

Some key tips to choose the right euro pallet nailing machine:

- Define Your Wood Pallet Production Needs

- Pallet Specifications: Identify the sizes (e.g., the common 1200mm×800mm) and types (e.g., EPAL standard pallets) your factory produces. Opt for a machine with customizable molds or compatibility with multiple sizes.

- Output Requirements: For small to medium factories with daily outputs of dozens to hundreds of pallets, a machine assembling 1-2 pallets per minute is sufficient, avoiding over-investment.

- Equipment Performance and Features

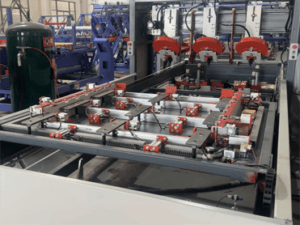

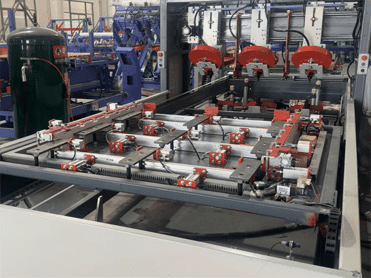

- Nail Gun Quantity: Choose a model with 6-9 nail guns to connect slats and blocks(Solid wood blocks and Wood chips pallet blocks) in one operation, boosting efficiency. The guns should support various nail sizes for flexibility across pallet designs.Automation Level: Semi-automatic machines (manual loading, automatic nailing) offer the best value for smaller factories. Fully automated options suit large-scale production but come at a higher cost.Dual-Station Design: Prioritize machines with two molds. Workers can prepare materials on one mold while the other assembles a pallet, enhancing productivity.

- Budget and Space Considerations

- Cost: With limited budgets, focus on mid-range machines. Prices for horizontal dual-station nailing machines typically range from tens of thousands to over a hundred thousand RMB, depending on brand and features.

- Footprint: Compact machines are ideal for space-constrained factories. Horizontal designs often save more space than vertical ones.

- Operation and Maintenance

- Ease of Use: Select a machine that’s simple to operate with minimal training required. Features like touchscreen controls and pneumatic clamping enhance usability.

- Durability and Support: Opt for a reputable brand or supplier with reliable after-sales service to ensure long-term performance and timely repairs.

- Additional Considerations

- Safety: Ensure the machine includes safety features to prevent accidents during operation.

- Trial Run: Before purchasing, arrange a test with the supplier to confirm the machine meets your specific requirements.

Final Tip: For small and medium factories, a semi-automatic, dual-mold machine with 9 nail guns—like our Horizontal European Pallet Nailing Machine—strikes the perfect balance of efficiency and affordability. Contact us to learn more or schedule a demo!