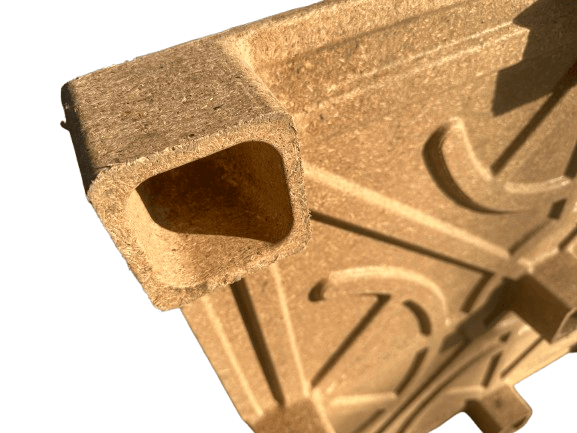

Molded pallets often develop burrs on their edges, which can affect their quality and usability. Understanding the causes of burrs and how to address them is essential for maintaining high standards in pallet production. Below, we explore the reasons behind burr formation, the benefits of advanced machinery, and effective methods for removing burrs.

Why Do Molded Pallets Develop Burrs?

Burrs on molded pallets typically arise from two main factors:

- Mold Wear and Press Deformation

Over time, molds wear down, and the press machine may experience slight structural deformation. This leads to imprecise mold closure, allowing wood chips to get trapped between the upper mold and the cavity, resulting in burrs. - Imprecise Mold Design

Due to limitations in machine precision or production techniques, some manufacturers design molds with larger tolerances. This increased gap between the upper mold and the cavity compensates for poor mold closure accuracy, preventing damage to the machine. However, this design choice often leads to burr formation.

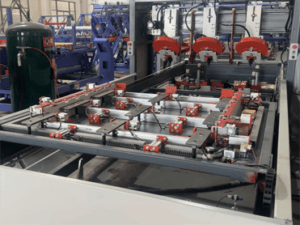

Benefits of Three-Beam, Four-Column Press Machines

For superior precision, opt for a three-beam, four-column molded pallet press. Unlike frame-style presses, these machines use four columns as guides, ensuring no deviation during operation. Their stable structure prevents frame deformation, delivering more accurate mold closure. This reduces the likelihood of burrs, enhancing the overall quality of the pallets.

When selecting a molded pallet equipment supplier, prioritize manufacturers offering three-beam, four-column presses and in-house mold design and production capabilities. These companies bring extensive experience in both machinery and mold development, ensuring reliable performance.

How to Remove Burrs from Molded Pallets

The method for removing burrs depends on their thickness and extent:

- Thin or Minor Burrs

For light burrs, simply wear gloves and gently wipe them away by hand. This quick fix works well for minimal imperfections. - Thick or Stubborn Burrs

When burrs are thicker and more complex to remove manually, use an angle grinder or a specialized edge-trimming machine. These tools efficiently smooth out the edges, restoring the pallet’s functionality and appearance.

Choose Trusted Manufacturers for Molded Pallet Solutions

For top-quality molded pallet machinery, consider industry leaders like PalletsBiz and PresswoodMachine. As pioneers in the field, PalletsBiz stands out with its comprehensive supply chain—from press machines to mold design and manufacturing. With decades of expertise, they deliver reliable, burr-free pallet production solutions. Contact them today to elevate your presswood pallet manufacturing process!