In pursuing sustainable and cost-effective packaging solutions, molded pallets are gaining popularity across various industries. But can agricultural waste like rice husk be used to make pallets? The answer is yes, and it offers significant advantages. In this article, we explore how rice husk can become a valuable resource in molded pallet production and how PalletsBiz can help you turn this idea into a profitable business.

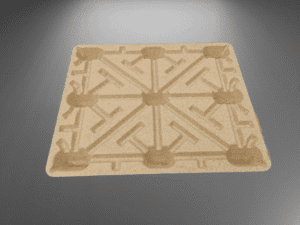

What Is a Molded Pallet?

Molded pallets—compressed pallets or presswood pallets—are made from compressed biomass materials using high pressure and heat. Unlike traditional wooden pallets, they are:

- Nail-free and splinter-free

- ISPM 15 compliant (no fumigation required for export)

- Space-saving and nestable

- Eco-friendly and recyclable

Posts about Molded Pallets advantages:

1. Rice Husk Presswood Pallets

2. Presswood pallet and complete the presswood pallet production line

3. Why are molded pallets the transportation solutions?

4. Top five benefits of using presswood wood pallets

Common raw materials for molded pallets include:

- Wood shavings

- Sawdust

- Straw

- Coconut husks

- Rice husks

These materials are typically agricultural or forestry waste, making molded pallets a greener alternative to plastic or traditional wooden pallets.

Based on our experience and testing, a large amount of biomass waste is maliciously used to make pallets. Please refer to the article below:

Pressed Pallets Production Raw Material

What Is Rice Husk Used For?

Rice husk is the outer shell of rice grains, removed during milling. With over 120 million tons produced annually worldwide (FAO), it is one of the most abundant forms of agricultural waste.

Mainstream applications of rice husk include:

- Biomass fuel for boilers and power plants

- Silica extraction for construction and industrial uses

- Animal feed additives

- Composite boards and biodegradable packaging

Key characteristics of rice husk:

- Lightweight and porous

- High silica content (up to 20%)

- Thermally stable

- Naturally moisture-resistant

These features make rice husk suitable for thermal compression molding—an essential step in pallet production.

Why Use Rice Husk to Make Molded Pallets?

✅ Material Compatibility

Rice husk is rich in fibrous cellulose and silica, which provides structure and bonding strength when mixed with adhesives like UF, MUF, or MDI glue. This makes it highly suitable for compression molding technology.

✅ Cost Advantages

- Abundant and inexpensive in rice-producing regions like Southeast Asia, India, and China.

- Reduces raw material costs by up to 40% compared to wood fibers.

- Reduces environmental disposal costs for rice mills.

✅ Sustainability Benefits

- Promotes zero-waste manufacturing

- Reduces carbon emissions by avoiding open-field burning

- Complies with green packaging requirements in the EU, USA, and more

Using rice husk to produce pallets helps businesses meet ESG and sustainability goals while lowering operational costs.

Market Potential of Rice Husk Molded Pallets

The demand for sustainable packaging materials is growing rapidly. According to Statista, the global pallet market is projected to reach USD 110 billion by 2030, with eco-friendly alternatives seeing the fastest growth.

Rice husk molded pallets are ideal for:

- Export logistics

- Agriculture and the fertilizer industry

- Warehousing and e-commerce

- Cold chain logistics

As governments tighten regulations on plastic and untreated wood, biodegradable and recyclable pallets are set to become mainstream.

Posts about India Pallet Market:

Molded Pallet Analysis of the India Market

India Pallet Market Analysis

The Evolving Landscape of the Indian Pallet Market

Why Choose PalletsBiz for Rice Husk Pallet Production?

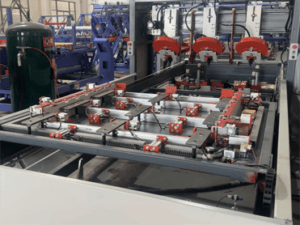

PalletsBiz is one of the earliest manufacturers in China to develop and produce molded pallet machines. With over a decade of industry experience, we have established a strong R&D team and a complete in-house production system—from custom mold design to hydraulic press machine manufacturing.

Our full in-house control ensures stable equipment quality and reliable delivery times. All of our machines are export-ready and fully compliant with international standards, making them ideal for global customers.

We also offer customized solutions tailored to your raw materials, pallet size requirements, and production goals. Whether you’re in Asia, Europe, Africa, or the Americas, PalletsBiz is your reliable partner in building an efficient and sustainable pallet production line.

At PalletsBiz, we specialize in molded pallet machines designed for flexibility, efficiency, and eco-friendliness. Our equipment supports a wide variety of raw materials, including rice husk, and can be customized to fit your production goals.

We offer:

- 🌿 Advanced compression molding machines

- 🛠️ Custom mold design and fabrication

- 🌍 Turnkey solutions from raw material to installation

- 🤝 Remote support and technical guidance

With years of industry experience and a passion for sustainable manufacturing, PalletsBiz is your trusted partner in building a profitable, eco-conscious pallet business.

📩 Ready to Start Making Rice Husk Pallets?

Contact PalletsBiz today to discover how our molded pallet machines can help you turn rice husk into a valuable packaging solution.