In the world of logistics and supply chain management, pallets play a crucial role in the efficient transportation and storage of goods. Among the various types of pallets available, molded pallet, also known as presswood pallets, have gained significant popularity due to their durability, cost-effectiveness, and eco-friendliness. However, one common concern that often arises is their water resistance.

In this article, we will delve into the factors that influence the waterproof capabilities of molded pallets, exploring aspects such as the pressure exerted by the pallet molding machine, the raw materials used, the type of adhesive applied, and the environmental conditions they are subjected to.

Factors Affecting Molded Pallet Water Resistance:

- Pressing Pressure:

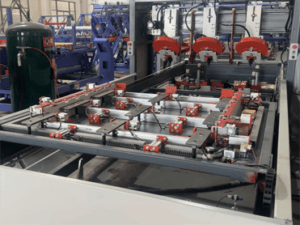

- The presswood pallet machine utilizes high pressure to compress wood fibers and resins into a solid, dense structure. This high-pressure process significantly reduces the porosity of the pallet, making it less susceptible to water absorption.

- According to industry standards, the pressure applied during the molding process can range from 50 to 80 bar. This high-pressure compaction enhances the density of the pallet, thereby improving its resistance to moisture.

- You can visit our website to see different types of presswood pallet machines.

- Raw Materials:

- The quality and type of raw materials used in the production of molded pallets play a vital role in their water resistance.

- Typically, these pallets are made from wood fibers, which are by-products of the timber industry. However, some manufacturers also incorporate waste plastic into the mix, further enhancing the pallet’s resistance to moisture.

- Using recycled materials is a good way to protect our environment, and palletsbiz.com has a lot of information about recycled pallets.

- Adhesive (Glue):

- The adhesive used to bind the wood fibers together is another crucial factor that influences the waterproof properties of molded pallet.

- Manufacturers often use water-resistant resins, such as phenolic resins or melamine-urea-formaldehyde (MUF) resins, which provide excellent moisture resistance.

- These resins create a strong, hydrophobic bond between the wood fibers, preventing water from penetrating the pallet’s structure.

- Environmental Conditions:

- While molded pallet offer a certain degree of water resistance, prolonged exposure to excessive moisture or standing water can still lead to water absorption and potential damage.

- Therefore, it is essential to store and use molded pallets in well-ventilated areas and avoid prolonged contact with water.

Enhancing Water Resistance:

- To further enhance the waterproof capabilities of molded pallets, some manufacturers apply a protective coating or sealant to the pallet’s surface.

- These coatings act as a barrier, preventing water from penetrating the pallet’s structure and increasing its overall durability.

Data and Credibility:

- According to a study by the European Pallet Association (EPAL), molded pallets exhibit a water absorption rate of less than 15% after 24 hours of immersion. This data highlights their inherent water resistance.

- You can find more information about pallets on palletsbiz.com.

Conclusion:

- In conclusion, molded pallets offer a commendable level of water resistance, making them a reliable choice for various logistics and storage applications.

- By understanding the factors that influence their waterproof capabilities and taking appropriate precautions, businesses can maximize the lifespan and performance of their molded pallets.