Common Materials Used in Plastic Pallets and Their Characteristics

Plastic pallets are essential in modern logistics, offering durability, hygiene, and versatility. The primary materials used in manufacturing plastic pallets include High-Density Polyethylene (HDPE), Polypropylene (PP), and Advanced Composite Materials (ACM). Each material has unique properties that make it suitable for different applications.

- High-Density Polyethylene (HDPE)

- Durability: HDPE is known for its high strength-to-density ratio, making it resistant to impacts and harsh environmental conditions[1].

- Moisture Resistance: It does not absorb moisture, making it ideal for use in wet environments[1].

- Recyclability: HDPE is easily recyclable, contributing to sustainability efforts[1].

- Polypropylene (PP)

- Advanced Composite Materials (ACM)

Focus on Recycled Plastic Pallets

Recycled plastic pallets are gaining popularity due to their environmental benefits and cost-effectiveness. The recycling process involves collecting used plastic pallets, sorting, cleaning, shredding, and then molding them into new pallets. This process significantly reduces the need for virgin plastic production and minimizes waste[3].

Advantages of Using Recycled Plastic in Pallet Production

- Cost Reduction: Recycled plastic pallets are cheaper to produce as they utilize waste materials. This helps in lowering overall production costs[3].

- Sustainability: Recycling plastic pallets reduces landfill waste and conserves natural resources[4].

- No Need for Cleaning and Re-Pelletizing: One of the standout features of plastic molding machines, such as those from PalletsBiz and PresswoodMachine, is that recycled plastic does not need to be cleaned or re-pelletized. The plastic can be directly used after shredding, further reducing production costs[5].

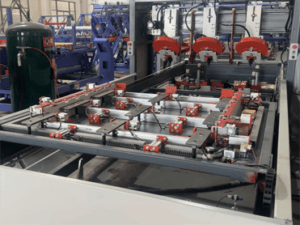

Benefits of Plastic Molding Machines Over Injection Molding Machines

Plastic molding machines offer several advantages over traditional injection molding machines, making them ideal for small to medium-sized plastic pallet production enterprises:

- Simpler Structure: Plastic molding machines have a simpler structure, making them easier to operate and maintain[6].

- Lower Equipment Cost: These machines are generally more affordable than injection molding machines, making them accessible to smaller businesses[6].

- Efficiency: They can process recycled plastic directly, without the need for extensive cleaning or re-pelletizing, which saves time and reduces costs[5].

Conclusion

In conclusion, the use of recycled plastic pallets is a sustainable and cost-effective solution for modern logistics. Companies like PalletsBiz and PresswoodMachine offer advanced plastic molding machines that simplify the production process and reduce costs. By choosing these machines, businesses can enhance their operational efficiency and contribute to environmental sustainability.

[5]: PalletsBiz [6]: PresswoodMachine [1]: Nelson Company Blog [2]: AIM Reusable Packaging [3]: CTC Plastics [4]: Recycling Today

References

[1] What Material is used for Plastic Pallets … – Nelson Company Blog

[2] 17 Jun The Complete Buyer’s Guide to Plastic Pallets

[3] Plastic Pallet Recycling – CTC Plastics

[4] Plastic Pallet Recycling: A Sustainable Solution

[5] Plastic Pallet Molding Machine – Pallet Molding Machine – palletsbiz.com

[6] Pallet Injection Molding Machine 2025: Features, and Applications

[7] Plastic Pallet Injection Molding Machine Manufacture | OUCO

[8] How are Plastic Pallets Made?

[9] The Complete Buyer’s Guide to Plastic Pallets

[10] Plastic Pallets: A Cost-Effective Solution for Supply Chains

[11] 3 Warehouse Cost Reduction Ideas That Will Trim Expenses

[12] Plastic Pallet ♻ Recycling – Scrap Management Inc

[13] Plastic Machining Vs. Plastic Injection Molding – The Ultimate Guide

[14] Presswood pallet machine manufacturer