Plastic pallets have become an essential tool in modern logistics and supply chain management, offering durability, lightweight design, and resistance to moisture and chemicals. But have you ever wondered what materials go into making these pallets? In this article, we’ll explore the common types of plastics used to manufacture plastic pallets and discuss which plastics are suitable for recycling into new pallets. We’ll also touch on the role of plastic pallet molding machines in this process and the importance of recycling in creating a sustainable future.

Common Plastics Used in Plastic Pallets

Plastic pallets are typically made from a variety of polymers, each chosen for its specific properties like strength, flexibility, and cost-effectiveness. the most commonly used plastics for pallets include:

- High-Density Polyethylene (HDPE)

HDPE is a standout choice for plastic pallets due to its excellent strength-to-weight ratio, impact resistance, and durability. It’s widely used in industries requiring robust pallets that can withstand heavy loads and repeated use. Additionally, HDPE is resistant to weathering and chemicals, making it ideal for outdoor storage and transportation. - Polypropylene (PP)

Polypropylene is another popular material for plastic pallets. Known for its rigidity and resistance to fatigue, PP pallets are lightweight yet capable of supporting significant weight. This plastic also performs well under varying temperatures, which makes it suitable for cold storage or high-heat environments. - Polyethylene (PE)

While HDPE is a specific type of polyethylene, other variations of PE, such as low-density polyethylene (LDPE), may occasionally be blended into pallet production for added flexibility. However, HDPE remains the dominant form due to its superior strength.

These materials are molded into pallets using advanced machinery, such as plastic pallet molding machines, which we’ll discuss later. The choice of plastic often depends on the intended application, cost considerations, and sustainability goals.

Plastics Suitable for Recycling into Plastic Pallets

Recycling is a critical aspect of reducing waste and promoting a circular economy, especially in the world of plastic pallets. While many plastics can technically be recycled, some are better suited for creating new pallets due to their properties and availability in the recycling stream. here are the key plastics that can be effectively recycled into plastic pallets:

- High-Density Polyethylene (HDPE)

HDPE is not only a common material for virgin plastic pallets but also a champion in recycling. Recycled HDPE retains much of its strength and durability, making it an excellent candidate for producing new pallets. Its widespread use in packaging (like milk jugs and detergent bottles) ensures a steady supply of recyclable material. - Polypropylene (PP)

PP is another recyclable plastic that can be repurposed into pallets. While it may lose some of its original properties during recycling, advancements in processing technology allow manufacturers to reinforce recycled PP, ensuring it meets the demands of pallet production. PP is commonly found in items like food containers and automotive parts, contributing to its availability for recycling.

These recycled plastics are collected, cleaned, shredded, and melted down before being fed into plastic pallet molding machines to create new, eco-friendly pallets. By using recycled materials, manufacturers can reduce their reliance on virgin plastics, lower production costs, and minimize environmental impact.

The Role of Plastic Pallet Molding Machines

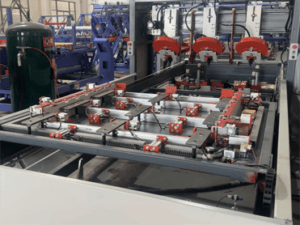

The production of plastic pallets—whether from virgin or recycled materials—relies heavily on specialized equipment known as plastic pallet molding machines.

When it comes to recycling, these machines play a pivotal role in transforming discarded plastics into functional products. The process begins with sorting and cleaning the recycled HDPE or PP, followed by melting it into a workable form. The molten plastic is then fed into the molding machine, where it’s shaped into a pallet under a high pressure of 1600 tons. Modern molding machines are designed to handle recycled materials efficiently, ensuring that sustainability doesn’t compromise quality.

The Importance of Recycling Plastic Pallets

Recycling plastic pallets is more than just a trend—it’s a necessity for a sustainable future. By repurposing materials like HDPE and PP, we can reduce landfill waste, conserve natural resources, and lower the carbon footprint of pallet production. Companies that adopt recycled plastic pallets also benefit from cost savings and an enhanced reputation for environmental responsibility.

Moreover, the durability of plastics like HDPE and PP means that recycled pallets can perform just as well as their virgin counterparts, making them a practical choice for businesses. As recycling technology advances and plastic pallet molding machines become more sophisticated, the quality and availability of recycled pallets will only improve.

Not only plastic pallets, but plastic molding machines can also utilize waste plastics to produce other products such as plastic roof tiles, plastic building formworks, and plastic sheets.

Conclusion

Plastic pallets, commonly made from materials like HDPE and PP, are a cornerstone of efficient logistics. When it comes to recycling, these same plastics stand out as ideal candidates for creating new pallets, thanks to their strength and recyclability.

With the help of plastic pallet molding machines, the industry is moving toward a more sustainable model, where recycled materials play a starring role. By embracing recycling, we can ensure that plastic pallets not only serve our immediate needs but also contribute to a greener, more responsible world.