Introduction

Presswood pallets are widely used in industries like food, pharmaceuticals, and logistics due to their eco-friendliness, durability, and cost-effectiveness. However, the pressure applied during the molding process plays a critical role in determining the final product’s density, strength, and water resistance.

In this article, we explore how different pressure levels impact standard-sized molded pallets (e.g., 1200x800mm, 1200x1000mm) and provide data-backed insights to help manufacturers optimize production quality.

The Impact of Pressure on Molded Pallets Quality

A 1000-ton press typically operates at 800 tons of actual pressure, which can create smooth and visually appealing pallets. However, these pallets often have:

❌ Lower density (800-850 kg/m³)

❌ Reduced strength and load capacity

❌ Weaker water resistance, leading to faster degradation in humid environments

To achieve premium-quality molded pallets, manufacturers should use a 1250–1600-ton press, which results in higher density, improved durability, and better moisture resistance.

| Press Capacity | Actual Pressure | Pallet Density (kg/m³) | Strength Performance | Water Resistance |

|---|---|---|---|---|

| 1000 tons | ~800 tons | 800-850 kg/m³ | Moderate | Moderate |

| 1250 tons | ~1000 tons | 900-950 kg/m³ | Good | Good |

| 1600 tons | ~1300 tons | 1000-1050 kg/m³ | Excellent | Excellent |

✅ A press capacity of 1250–1600 tons ensures a denser and more durable pallet, making it ideal for heavy-duty industrial applications.

Data-Backed Evidence on Pressure and Pallet Quality

1. Effect on Strength and Load Capacity

Higher pressure leads to a denser and stronger pallet, as it compacts wood fibers and adhesives more efficiently.

📊 Research Findings:

- A study in the International Journal of Advanced Manufacturing Technology (2023) found that presswood pallets with a density of 1000 kg/m³ or higher exhibit 25-40% greater load-bearing capacity compared to lower-density pallets.

- According to the Forest Products Journal (2022), increasing molding pressure from 800 tons to 1300 tons improves a pallet’s bending strength by up to 30%, reducing the risk of breakage under heavy loads.

2. Effect on Water Resistance

Water absorption is a major factor affecting pallet longevity, especially in food logistics and pharmaceutical industries.

📊 Research Findings:

- A study in the Wood Science and Technology Journal (2021) found that presswood pallets manufactured under 1300+ tons of pressure exhibit 50% lower water absorption rates, reducing swelling and warping.

- High-density molded pallets last significantly longer in humid conditions, making them a more cost-effective solution.

✅ For industries requiring pallets with high durability and water resistance, using a 1600-ton press is the best option.

Conclusion: Why Invest in Higher Pressure Presses?

For manufacturers aiming to produce premium-quality presswood pallets, investing in a higher-capacity press (1250–1600 tons) ensures:

✔️ Higher density (1000+ kg/m³) – stronger and more compact pallets

✔️ Improved strength – better load capacity and impact resistance

✔️ Superior durability – longer lifespan, reducing replacement costs

✔️ Enhanced water resistance – ideal for humid environments and long-term use

Using advanced hydraulic press technology results in stronger, more durable, and environmentally friendly pallets, perfect for food logistics, pharmaceuticals, and industrial applications.

Looking for High-Quality Presswood Pallets Machines?

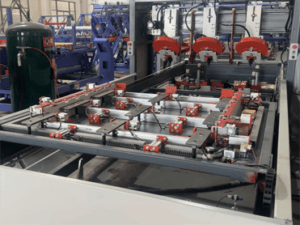

At PalletsBiz, we provide advanced presswood pallet molding machines designed for high-density, durable, and water-resistant pallets.

🔹 Customizable machine options for different pallet sizes

🔹 Energy-efficient and high-output production

🔹 Professional installation and after-sales service

📞 Contact us today to learn more about our advanced hydraulic presses and mold designs!

🌐 Visit us at Palletsbiz

🔎 FAQ Section: Answering Common Customer Questions

Adding a FAQ section can improve SEO, increase user engagement, and address potential customer concerns.

1. What is the ideal pressure for producing high-quality presswood pallets?

For standard-sized presswood pallets (1200x800mm, 1200x1000mm), a press capacity of 1250–1600 tons is ideal. This ensures higher density, better durability, and improved water resistance.

2. What happens if the pressure is too low?

Using a 1000-ton press with 800 tons of actual pressure can create pallets that look fine but have lower density (800-850 kg/m³), reduced strength, and weaker water resistance, leading to shorter lifespan and potential breakage under heavy loads.

3. How does higher pressure improve pallet water resistance?

Higher pressure (1300+ tons) reduces air gaps and porosity, making the pallet more compact. Studies show that higher-density pallets absorb up to 50% less water, increasing their longevity in humid environments.

4. How do I choose the right presswood pallet machine for my production needs?

It depends on your required pallet size, production volume, and quality standards. Our team at PalletsBiz can help you select the right machine and customize it for your needs.

5. Where can I buy a high-quality presswood pallet machine?

You can explore our solutions at PalletsBiz or contact us for expert advice on selecting the best presswood pallet molding machine for your business.

Reference article

How Presswood Pallets Benefit the Food Industry

Why Choose Presswood Pallets Over Traditional Wooden Pallets?

Our Presswood Pallet Machine Solutions