Molded pallets, also known as presswood pallets or compressed wood pallets, are gaining popularity due to their durability, lightweight design, and environmental benefits. But how much weight can they support? This article explores the load-bearing capacity of molded pallets, the factors that influence their strength, and how they compare to traditional wooden and plastic pallets.

Types of Load Capacities for Presswood Pallets

When selecting a pallet for your business, it’s essential to understand its load capacity. they are categorized into three main load types:

1. Static Load Capacity

A pallet’s static load refers to the maximum weight it can support while resting on a flat surface without being moved. Molded pallets typically have a static load capacity of up to 6,000 kg (13,200 lbs), making them ideal for heavy-duty storage applications.

2. Dynamic Load Capacity

The dynamic load is the weight a pallet can carry while being lifted or transported by a forklift or pallet jack. Molded pallets generally support between 1,500 kg and 2,500 kg (3,300–5,500 lbs) in dynamic loads, depending on their size and material composition.

3. Racking Load Capacity

Racking load is crucial for warehouse storage, as it determines the weight a pallet can hold while placed on a racking system with no support underneath. Most presswood pallets have a racking load capacity of up to 1,000 kg (2,200 lbs), although this varies based on design and reinforcement.

Factors That Affect Presswood Pallet Strength

Several factors influence how much weight a compressed wood pallet can handle:

1. Material Composition

Presswood pallets are manufactured using wood fiber and adhesives such as UF (Urea-Formaldehyde), MUF (Melamine-Urea-Formaldehyde), or MDI (Methylene Diphenyl Diisocyanate). The type of resin used affects the pallet’s strength, durability, and moisture resistance.

2. Manufacturing Process

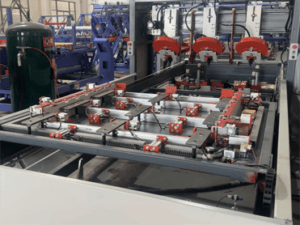

Molded pallets are produced through a high-pressure compression molding process, ensuring uniform density and structural stability. The compression process significantly enhances their load-bearing capacity compared to traditional wooden pallets.

3. Structural Design

- Nestable pallets are designed to save space but may have slightly lower load capacities.

- Reinforced rib designs provide extra strength for racking applications.

- Thicker molding increases overall durability and weight tolerance.

4. Environmental Conditions

Although Presswood pallets are treated to resist moisture and pests, extreme humidity or temperature changes can affect their performance. Proper storage in dry conditions helps maintain their structural integrity.

Why Choose a Compressed Pallet for Heavy Loads?

Presswood pallets offer several advantages for businesses handling heavy goods:

✅ Eco-Friendly – Made from recycled wood fibers, reducing waste.

✅ Cost-Effective – Lightweight design lowers shipping costs.

✅ ISPM 15 Exempt – No fumigation required for export.

✅ Strong & Durable – High load-bearing capacity for various applications.

Presswood Pallets Industry Applications

Due to their strength and compliance with international shipping regulations, molded pallets are widely used in industries such as:

- Food & Beverage – Hygienic and ISPM 15-compliant for global shipments.

- Pharmaceuticals – Safe for transporting sensitive products.

- Electronics – Lightweight yet durable for fragile items.

- Automotive – Capable of handling heavy machinery parts.

Comparison: Molded Pallets vs. Plastic & Traditional Wood Pallets

| Feature | Molded Pallets | Plastic Pallets | Traditional Wood Pallets |

|---|---|---|---|

| Weight Capacity | High | High | Moderate |

| Eco-Friendliness | Yes | No | Yes |

| ISPM 15 Exempt | Yes | Yes | No |

| Durability | High | Very High | Moderate |

| Cost-Effectiveness | High | Low | Moderate |

Frequently Asked Questions (FAQs)

1. What is the difference between static and dynamic load?

- The static load is the weight a pallet can support while stationary.

- Dynamic load refers to the weight a pallet can carry while being lifted or moved.

2. Can molded pallets be used for export?

Yes! Molded pallets are ISPM 15-exempt, making them a hassle-free option for international shipping.

3. Are compressed wood pallets better than plastic pallets?

It depends on your needs! Presswood pallets are eco-friendly, cost-effective, and strong, while plastic pallets have superior durability but higher costs.

Conclusion

The load capacity of presswood pallets makes them a reliable choice for warehousing, logistics, and international shipping. Whether you need high static load support for storage or durable dynamic load capacity for transport, molded pallets offer a strong, cost-effective, and eco-friendly solution.

At PalletsBiz, we specialize in providing high-quality molded pallet machines and molds to help businesses manufacture durable, customizable pallets. Contact us today to learn more about molded pallet production and how it can benefit your supply chain!