Molded pallets have gained significant popularity in recent years, becoming a go-to choice for many customers worldwide. These innovative pallets are increasingly recognized and accepted due to their versatility, durability, and cost-effectiveness. The demand for molded pallets has surged rapidly, with usage growing across various industries and applications. Depending on their design and style, molded pallets cater to different needs, making them a flexible solution for logistics, storage, and transportation.

In this article, we’ll explore the different styles of molded pallets, their features, benefits, and specific uses. Whether you’re looking for a traditional option or a cutting-edge design, there’s a molded pallet style to suit your needs.

1. Nine-Foot Molded Pallet: The Classic Choice

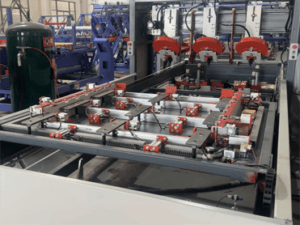

The nine-foot molded pallet is the most traditional and widely used style. It’s a simple, reliable option manufactured using pallet molding machines with pressures of 800, 1,000, 1,250, or 1,600 tons. For optimal results, experts recommend using a 1,250-ton or 1,600-ton press. This pallet is produced in a single molding process with specialized MDI glue, allowing for a production rate of 10-15 pallets per hour.

- Weight: Ranges from 10 kg to 25 kg

- Dynamic Load Capacity: 500 kg to 2,500 kg

- Stacking: Up to 41 pallets can be stacked to a height of 2 meters

Advantages: Its stackable design saves significant space during transportation and storage, reducing costs.

Disadvantages: The nine feet on the surface create small cavities, which may affect the stability of items like beverage bottles or cartons. It’s also not suitable for roller conveyor systems in production lines.

For more details on container loading capacities, refer to related articles online.

2. Double-Layer Molded Pallet: An Upgraded Design

The double-deck molded pallet is an improved version of the nine-foot style. It can also be made using 800, 1,000, 1,250, or 1,600-ton presses. However, since it consists of two combined layers, its weight is 1.2 to 2 times heavier than a standard pallet. This design requires at least two presses for production, cutting efficiency to about half that of the nine-foot pallet.

- Key Features: Reduced or eliminated surface cavities, making it ideal for roller conveyors and shelf storage.

- Benefits: Offers excellent dynamic load capacity and versatility.

This style is perfect for businesses needing a sturdier pallet for automated systems or heavier goods.

3. Rackable Molded Pallet: Built for Shelving

Similar to the nine-foot pallet, the rackable molded pallet is designed specifically for use on shelves and automated roller conveyors. Its sturdy construction ensures stability when stored on racks, making it a favorite in warehouses and distribution centers.

- Best For: Companies with automated systems or shelving needs.

- Why It Stands Out: Combines durability with compatibility for modern logistics setups.

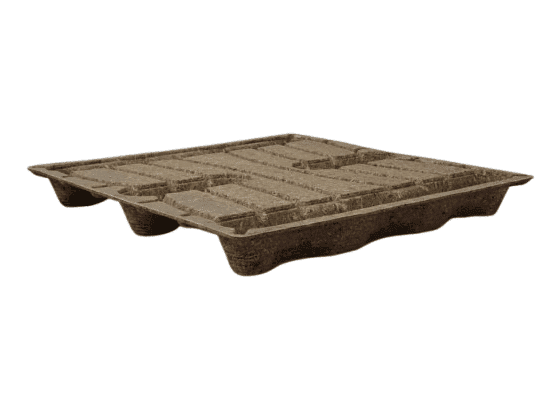

4. Flat-Surface Molded Pallet: The Modern Innovation

Developed recently by PalletsBiz, the flat-surface molded pallet is a game-changer. Produced using a 1,600-ton press and MDI glue, it maintains a production rate of 10-15 pallets per hour.

- Weight: 15 kg to 25 kg

- Load Capacity: 500 kg to 2,500 kg

- Unique Feature: A completely flat surface for superior load stability.

Advantages: Its smooth design protects goods from damage and supports any type of cargo. With minor adjustments, it’s compatible with roller conveyors. This style is currently the most popular molded pallet on the market due to its versatility and performance.

5. Solar Panel Molded Pallet: Tailored for the Solar Industry

Designed by PalletsBiz for solar panel manufacturers in China and Southeast Asia, this pallet meets the unique needs of the photovoltaic industry. It measures 2,500 x 1,300 mm and weighs 45-50 kg.

- Benefits: Stackable design cuts transportation and storage costs. Compared to traditional solid wood solar pallets, it’s lighter and more cost-effective.

- Market Impact: Vietnamese clients have already signed contracts with PalletsBiz, marking the first overseas order for this style in the Chinese solar panel pallet press market.

The Future of Molded Pallets

Companies like PalletsBiz and PresswoodMachine are continuously innovating, and developing new molded pallet styles to meet diverse industry demands. From logistics to renewable energy, molded pallets are proving to be an eco-friendly, efficient alternative to traditional options. According to industry reports, the global molded pallet market is expected to grow steadily, driven by its sustainability and adaptability.

For any questions or specific molded pallet needs, contact PalletsBiz—the industry leader in molded pallet machines and solutions.