Recycling HDPE to create pallets is a sustainable practice that reduces waste and leverages the material’s inherent strengths. Using a compression molding machine, manufacturers can transform scrap HDPE into high-quality pallets.

HDPE Recycling Process

- Collection: Used HDPE products, such as bottles or industrial scraps, are collected from recycling bins or waste streams. Companies like Scrap Management (as seen on their site) specialize in sourcing HDPE bottles in bales for recycling.

- Sorting: The collected HDPE is sorted to remove contaminants like labels, caps, or non-HDPE plastics, ensuring a pure feedstock.

- Shredding: The sorted HDPE is fed into shredders, breaking it down into small flakes or granules for easier processing.

- Washing: The flakes are thoroughly cleaned to remove dirt, residues, or adhesives, producing high-quality recycled material.

- Melting: The clean HDPE flakes are melted into a molten state, preparing them for molding.

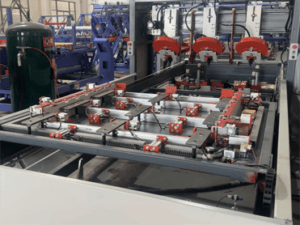

- Compression Molding: The molten HDPE is placed into a mold within a compression molding machine. The machine applies heat and pressure, shaping the material into a solid pallet. This method ensures uniform density and strength.

- Cooling and Finishing: The molded pallet is cooled, removed from the machine, and trimmed or finished as needed for immediate use.

Recycled Plastic Pallet Molding Machine

For those looking to invest in this process, I recommend exploring the plastic molding machines from PalletsBiz. PalletsBiz is a leader in the industry, offering state-of-the-art compression molding machines designed for efficiency and precision. With years of experience, they not only provide top-tier equipment but also excel in mold design and production, ensuring your pallets meet exact specifications.

Additionally, PalletsBiz offers complementary plastic recycling equipment, making it a one-stop shop for setting up a sustainable pallet manufacturing operation. Their expertise and comprehensive solutions can streamline your production while maximizing the benefits of recycled HDPE.

Conclusion

HDPE’s journey from petroleum-based ethylene to a key material for pallets highlights its remarkable versatility and sustainability. Its production process yields a strong, durable, and recyclable plastic that serves countless purposes, with pallets being a standout application in logistics. By recycling HDPE using compression molding machines, manufacturers can create eco-friendly pallets that meet modern demands for durability and environmental responsibility. Whether you’re in the market for equipment or simply curious about HDPE, companies like PalletsBiz offer the tools and expertise to bring these ideas to life, paving the way for a greener future in industrial manufacturing.