📖 Introduction

When using MDI (Methylene Diphenyl Diisocyanate) adhesive in presswood pallet production, its high bonding strength and rapid curing characteristics can easily cause pallets to stick to the mold if mold protection, temperature, or glue ratio are not properly controlled.

This guide explains the causes of mold adhesion, effective solutions, optimized operational recommendations, and emergency handling methods.

📌 Causes of Mold Adhesion with MDI Adhesive

- Uneven or insufficient application of mold release agent

- Incompatible release agent for MDI adhesive

- Excessive adhesive application, overflowing the pallet profile

- Excessively high hot-pressing temperature, causing adhesive carbonization and sticking

- Unreasonable forming pressure or holding time

📌 Solutions and Process Optimization

🛠️ 1. Check Mold Release Application

Ensure that the release agent is evenly sprayed before each molding cycle, especially on recessed and corner areas.

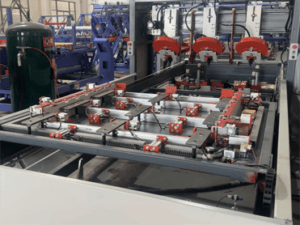

At PalletsBiz, we have designed a dedicated automatic spraying system for release agents, perfectly resolving mold adhesion problems on automated production lines.

Pro Tip: Always use the release agent recommended by your MDI adhesive supplier. This is crucial for performance.

🛠️ 2. Regular Mold Cleaning

After each production shift or batch, clean mold surfaces to remove residual adhesive and carbonized material. Spray anti-rust agent after cleaning.

🛠️ 3. Optimize Process Parameters

- Control adhesive dosage between 3% to 5% to avoid overflow, for different glue the ratio is not the same.

- Maintain hot-press temperature between 150°C and 180°C to prevent adhesive carbonization, mold temperature is essential for the production process.

- Adjust holding time between 180 and 240 seconds, based on raw material moisture content.

- Higher press machine pressure, for higher product quality and productivity, we suggest using 1250-ton or 1600-ton presswood pallet machines.

📌 Emergency Handling Methods (If Mold Adhesion Occurs)

- Gentle Tapping:

Use a soft tool to gently tap the mold edges without damaging the pallet. - Local Heating:

Slightly heat the stuck area to reduce adhesive viscosity before attempting demolding. - Solvent Cleaning:

Use a dedicated solvent (such as acetone — with strict safety precautions) to wipe off MDI adhesive residue from mold surfaces.

📞 Need Expert Assistance?

Feel free to contact PalletsBiz’s technical team for more tailored solutions and equipment recommendations.

Download:

Anti-Sticking and Demolding Management SOP

📚 Frequently Asked Questions (FAQ)

Q1: Why does MDI adhesive cause mold sticking more easily than other adhesives?

A: MDI adhesive has high bonding strength and rapid curing characteristics. If the release agent application or process parameters aren’t properly controlled, mold adhesion occurs easily.

Q2: Can I use any release agent with MDI adhesive?

A: No. You should always use the release agent recommended by your adhesive supplier or specifically formulated for MDI adhesives.

Q3: What’s the ideal hot-press temperature for using MDI adhesive?

A: Between 150°C and 180°C, depending on material moisture content.

Q4: How often should I clean the mold when using MDI adhesive?

A: After each production shift or batch, or immediately if visible residue builds up.