Presswood Pallet Molding Machine

- Lightweight & Strong: Lighter than wooden pallets, reducing costs while maintaining strength.

- Eco-Friendly: Made from recycled materials, sustainable and timber-saving.

- Space-saving: Nestable design optimizes storage.

- Pest-Free: Naturally pest-resistant, meets global shipping standards (e.g., ISPM 15).

- Consistent Quality: Uniform size and strength from automated production.

- Safe: No nails or splinters, safer for handling and goods.

- Cost-Effective: Durable and lightweight, offering long-term savings.

Presswood Pallet Machine

Presswood Pallet Machine 800 tons

Presswood Pallet Machine 1000 tons

Presswood Pallet Machine 1250 tons

Presswood Pallet Machine 1600 tons

Presswood Pallet Machine 2000 tons

Presswood Pallet Machine 3000 tons

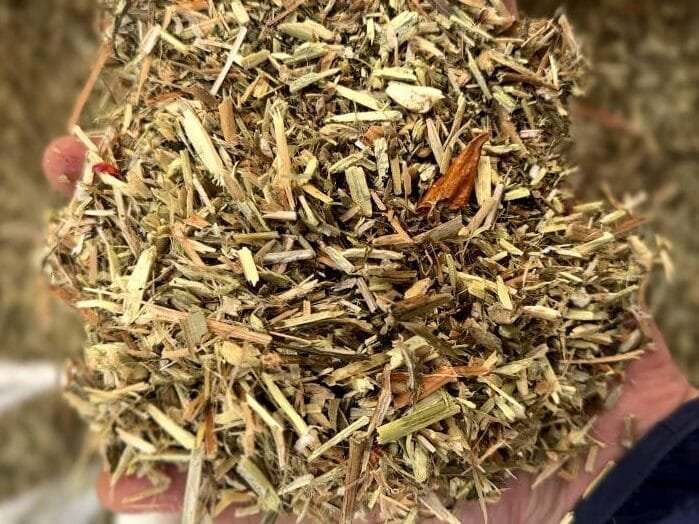

Raw Material For Presswood Pallet Production

Presswood Pallet Paterns

Nine Feet Pallet

Rackable Pallet

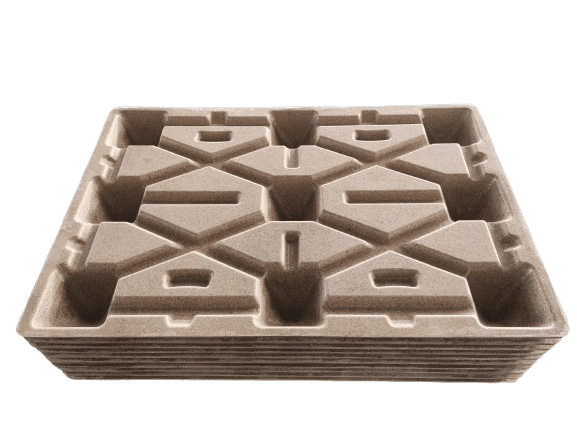

Double Deck Pallet

Solar Panel Pallet

Flat Surface Pallet

Presswood Pallet Sizes and Specifications

Presswood Machine: Min 1250 tons

Raw Material: Waste Wood, Wood Scraps

Pallet Weight: 18-22 kg

Specification: 4-way

Static load: 6t-9t

Dynamic load: 1.5t-2.5t

Logo: Custom

Cost comparable to timber

No splinters ,moisture, infestation

Heat treatment and fumigation not required

Durable and Reusable

100% Recyclable at end of life

Presswood Machine: Min 1250 tons

Raw Material: Waste Wood, Wood Scraps

Pallet Weight: 15-22 kg

Specification: 4-way

Static load: 6t-9t

Dynamic load: 1.5t-2.5t

Logo: Custom

Cost comparable to timber

No splinters ,moisture, infestation

Heat treatment and fumigation not required

Durable and Reusable

100% Recyclable at end of life

Presswood Machine: Min 1250 tons

Raw Material: Waste Wood, Wood Scraps

Pallet Weight: 10-15 kg

Specification: 4-way or 2-way

Static load: 2t-3t

Dynamic load: 0.5t-1.0t

Logo: Custom

Cost comparable to timber

No splinters ,moisture, infestation

Heat treatment and fumigation not required

Durable and Reusable

100% Recyclable at end of life

Presswood Machine: Min 1250 tons

Raw Material: Waste Wood, Wood Scraps

Pallet Weight: 10-20 kg

Specification: 4-way

Static load: 6t-9t

Dynamic load: 0.5t-1.5t

Logo: Custom

Cost comparable to timber

No splinters ,moisture, infestation

Heat treatment and fumigation not required

Durable and Reusable

100% Recyclable at end of life

Presswood Machine: Min 800 tons

Raw Material: Waste Wood, Wood Scraps

Specification: 4-way

Static load:4t-6t

Dynamic load: 0.5t-0.8t

Logo: Custom

Cost comparable to timber

No splinters ,moisture, infestation

Heat treatment and fumigation not required

Durable and Reusable

100% Recyclable at end of life

1. What are the standard sizes for presswood pallets?

The most common sizes for presswood pallets are:

1200 mm x 1000 mm (48″ x 40″) – This is the standard size for pallets used in North America and Europe.

1200 mm x 800 mm (48″ x 32″) – Often used in the European market for smaller loads.

1100 mm x 1100 mm (43″ x 43″) – Common in Asia, particularly for the logistics of certain bulk goods.

Sizes may vary depending on the specific requirements of customers or the logistics needs of a particular market.

2. Can presswood pallets be customized to different sizes?

Yes, one of the advantages of presswood pallets is their flexibility. They can be designed and manufactured to various sizes to accommodate specific customer requirements. Manufacturers like PalletsBiz offer custom sizes, which can range from small-scale pallets to larger sizes for industrial use.

3. Are there any industry standards that define presswood pallet sizes?

While there are no universal global standards for presswood pallets, certain sizes are considered standard in different regions. For example, the EU Pallet (1200 mm x 800 mm) is widely used in Europe, while 48″ x 40″ is a popular standard in North America. The ISO 6780 standard outlines general guidelines for pallet sizes and dimensions that are often referenced.

4. Why are presswood pallet sizes important?

The right pallet size ensures optimal use of storage space, easier transportation, and better handling of goods. Choosing the correct pallet size helps avoid product damage, minimizes shipping costs, and maximizes warehouse efficiency. In addition, standard pallet sizes can help businesses comply with international shipping regulations.

5. How do I choose the right presswood pallet size for my products?

When choosing the size of a presswood pallet, consider the following:

Product size and weight: Ensure the pallet can support the load and dimensions of your goods.

Storage requirements: Think about how the pallets will be stacked in your warehouse.

Shipping and handling: Make sure the pallet fits with your shipping logistics and meets industry standards.

Cost: Larger pallets might be more expensive, so choose a size that balances cost and function.

6. Can presswood pallets be used for all types of products?

Presswood pallets are suitable for a wide range of products, including heavy and bulky items. However, for very heavy or fragile products, a more robust pallet like a plastic or wooden one might be recommended. It is essential to assess the load capacity of the presswood pallet based on the product specifications.

7. How can presswood pallets be adapted for special use cases?

Presswood pallets can be adapted for special use cases through custom molding and reinforcement. For instance, for high-temperature environments or chemical handling, presswood pallets can be treated or combined with special coatings. Manufacturers can also design pallets with specific features like anti-slip surfaces or built-in slots for easy handling.

8. Are presswood pallets stackable?

Yes, presswood pallets are stackable, which makes them ideal for efficient use of storage space. The design of presswood pallets allows them to be stacked easily, ensuring better organization and reducing storage costs.

9. What is the load-bearing capacity of presswood pallets?

The load-bearing capacity of presswood pallets depends on factors like size, design, and the type of wood used. Standard presswood pallets can generally carry loads between 500 kg to 1500 kg (1100 lbs to 3300 lbs). For heavier loads, customized presswood pallets with reinforced designs can be produced.

10. How do presswood pallet sizes compare to other types of pallets?

Presswood pallets are generally lighter than wooden pallets and often offer a higher load-bearing capacity than plastic pallets of similar size. However, they can be more fragile than their solid wood counterparts, especially if exposed to moisture. When comparing different pallet types, it’s important to consider factors such as load capacity, weight, cost, and environmental impact.

Presswood Pallet Packing In Container

1. Size 1200x800x140mm Nine Feet Presswood | ||||||

|---|---|---|---|---|---|---|

| Container Type | Description | Weight | ||||

| 20 ft Container | 12 stacks x 55 pcs | 660 pcs | 10 tons | |||

| 40 ft Container | 23 stacks x 64 pcs | 1472 pcs | 22.08 tons | |||

| 45 ft Container | 32 stacks x 64 pcs | 30.75 tons | ||||

| 2. Size 1200x1000x140mm Nine Feet Presswood | 2. Size 1200x800x140mm Nine Feet Presswood | 2. Size 1200x800x140mm Nine Feet Presswood | 2. Size 1200x800x140mm Nine Feet Presswood | |||

| Container Type | Description | Quantity | Weight | |||

| 20 ft Container | 8 stacks x 55 pcs | 450 pcs | 7.65 tons | |||

| 40 ft OT Container | 18 stacks x 64 pcs | 1152 pcs | 19.58 tons | |||

| 45 ft Container | 24 stacks x 64 pcs | 1536 pcs | 26.11 tons | |||

| 3. Size 1100x1100x140mm Nine Feet Presswood | 3. Size 1100x1100x140mm Nine Feet Presswood | 3. Size 1100x1100x140mm Nine Feet Presswood | 3. Size 1100x1100x140mm Nine Feet Presswood | |||

| Container Type | Description | Quantity | Weight | |||

| 20 ft Container | 10 stacks x 55 pcs | 550 pcs | - | |||

| 20 ft OT Container | 10 stacks x 60 pcs | - | ||||

| 40 ft OT Container | 20 stacks x 64 pcs | 1100 pcs | - | |||

| 45 ft Container | 24 stacks x 64 pcs | 1540 pcs | - | |||

Other products that can be made with this machine

Molded Core Plugs

Molded core plugs offer superior protection against crush and side-impact damage, helping manufacturers avoid costly product losses and operational issues. Designed for paper, plastic film, and metallic foil converters, these plugs are made from a durable blend of hardwood, softwood, and resin, ensuring exceptional density and crush resistance. With industry-leading durability, provide reliable, cost-effective protection for your product rolls…

Molded Board - Kids Desk/Chair Board - Furniture Board

The pressed Kids chair desk board is a durable and sturdy piece of furniture crafted from high-quality solid wood with a molded desk board, offering superior durability compared to regular MDF or plywood laminated products. It features a modern design with a seamless, scratch-resistant, stain-resistant, weather-resistant, and heat-resistant surface that can even withstand cigarette burns, ensuring long-lasting use in commercial settings like schools or daycare centers. Available in a variety of contemporary colors, this desk board is water- and soy-proof, making it easy to clean, while its convertible feature allows it to adapt to different needs, providing versatile and reliable functionality for young users.

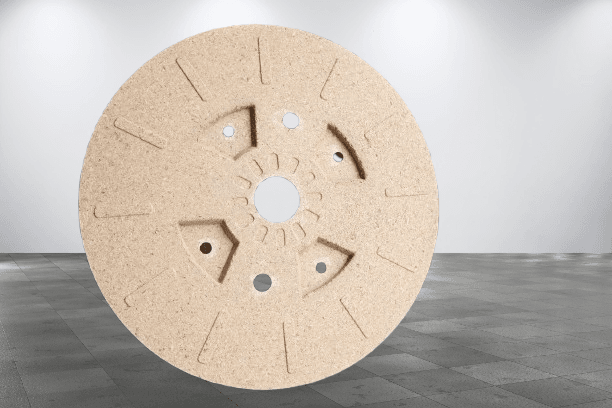

Molded Cable Drum Wheels

Cable reel wheels made from compressed wood chips or sawdust offer several advantages, including cost-effectiveness due to the use of recycled materials, lightweight yet sturdy construction for easy handling, and environmental sustainability as they repurpose waste into a functional product. Their molded design ensures durability and resistance to wear, while the natural properties of wood provide decent weather resistance, making them a practical and eco-friendly alternative to traditional materials like metal or plastic.

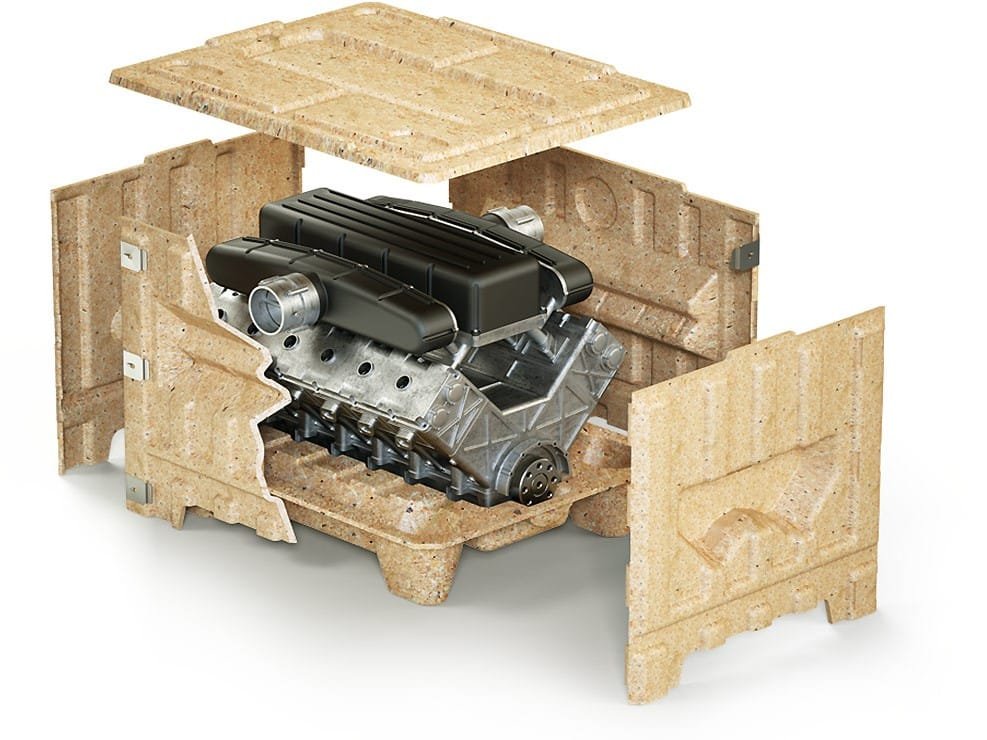

Molded Wooden Boxes

Wooden boxes made from compressed wood chips or sawdust provide a cost-effective and eco-friendly solution, utilizing recycled materials to create a lightweight yet robust structure ideal for storage or shipping. Their molded construction offers durability, resistance to minor impacts, and natural weather resilience, while the versatility of the material allows for customizable shapes and sizes, making them a sustainable alternative to conventional wooden or plastic crates.

Molded Euro Pallet Wood Chip Blocks

Euro pallet blocks made from compressed wood chips or sawdust offer a cost-efficient and sustainable option, leveraging recycled materials to produce lightweight yet strong components that meet European pallet standards. Their molded design ensures consistent durability, impact resistance, and sufficient load-bearing capacity, while the natural wood properties provide moderate weather resistance, making them an environmentally friendly and practical alternative to solid wood blocks.